2025.12.24

This article examines the importance of flour quality and safety as one of the essential food ingredients. It outlines the Iranian national standards for wheat, corn, barley, rice, and soybean flours, followed by a review of the parameters evaluated, the permissible limits of each test according to the relevant standards, the reasons for assessment, and the necessity of performing these tests. Additionally, the laboratory services that Marjaan Khatam Food Laboratories can provide in compliance with the National Standards Organization and the Food and Drug Administration are introduced.

Introduction

Flour is a powder typically produced by milling starchy sources such as corn, rice, barley, and soy. It is used in the production of various foods, including bread, pastries, cakes, biscuits, pasta, and many other products.

Iran has more than 400 flour mills, of which 380 are operational. Collectively, these mills can produce approximately 30 million tons of flour annually. However, domestic flour consumption is estimated at around 12 million tons per year, leaving a significant portion of production capacity over 18 million tons unused.

Considering Iran's geographical location and its proximity to major flour-importing countries such as Iraq, Afghanistan, and Syria, Iran has considerable potential to operate in regional markets. Nevertheless, due to challenges such as currency issues and lack of coordinated policies, Iran has not been able to secure a significant share of export markets in recent years.

Importance of Flour Quality

Flour is the primary ingredient in many food products such as bread and pasta. Since flour quality directly affects the texture, taste, volume and shelf life of the final product, quality control from grain reception to processing and packaging is highly important.

In the past, much of the flour was consumed domestically at the household level, but today, the majority of flour consumers are industrial and mechanized units such as large bakeries, pasta factories, and confectioneries. These units require flour with consistent specifications to produce high-quality products, as variations in flour properties can disrupt production. For instance, changes in flour protein content can affect water absorption and gas retention during dough fermentation, resulting in denser or excessively airy bread. Differences in moisture content or particle size can also impact mixing, kneading, or baking of pasta and cakes, ultimately reducing the quality of the final product. Therefore, consistency in flour properties is critical for industrial units to deliver products with uniform quality and characteristics.

Cereals are plant-based and influenced by environmental conditions, making variations in their physicochemical properties inevitable. It is unrealistic to expect flour of exactly the same quality from the same type of grain. However, using specialized knowledge and precise laboratory controls, natural flour properties are continuously measured so that production units can adjust their processes in response to any changes.

Thus, ensuring optimal flour quality depends not only on the characteristics of the grain and processing but also on continuous laboratory monitoring. Accordingly, various tests established by the National Standards Organization are performed in specialized food laboratories on flour samples to evaluate their properties.

Common Flour Tests and Reasons for Their Importance

Flours derived from different grains have different characteristics, and each type of flour has a specific standard that serves as the official reference for quality evaluation and control. These standards include:

- National Standard for Wheat Flour: 103

- National Standard for Rice Flour: 11136

- National Standard for Corn Flour: 8151

- National Standard for Soy Flour: 2357

- National Standard for Barley Flour: 2337

- Appearance Characteristics

Examining the appearance of flour plays a crucial role in assessing quality and detecting freshness or spoilage. Key appearance indicators include odor, taste, color, texture, and signs of contamination:

- Odor: Fresh flour should have a natural, pleasant aroma. Any unusual smell, such as moldiness or rancidity, may indicate aging, spoilage, or contamination.

- Taste: Fresh flour should have its characteristic taste, without any unusual flavors such as bitterness or pungency.

- Color: Flour color should be natural and appropriate for its type. For example, freshly milled refined flours (white flour) are white to light cream, while aged flour may appear yellowish, gray, or reddish.

- Physicochemical Properties

Physicochemical tests comprise a set of experiments that examine the physical and chemical properties of a substance, such as moisture, ash, acidity, and more.

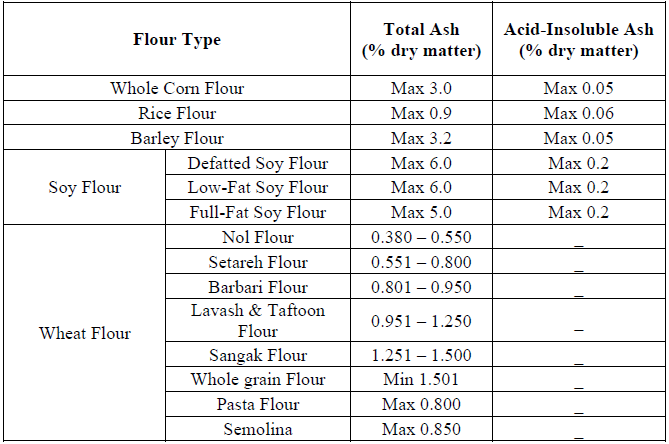

- Total Ash and Acid-Insoluble Ash

Ash tests determine the amount of inorganic impurities such as bran, minerals, and, in some cases, environmental contaminants present in flour. Since most of the flour's minerals are in the bran, the ash content reflects the amount of bran remaining after milling. In other words, this index indicates the purity of flour and the efficiency of the bran separation process (removal of the outer protective layer of the grain from the endosperm, the inner layer).

Total ash content represents the total mineral content of the flour. The flour sample is incinerated, and the minerals in the ash are measured. In the acid-insoluble ash method, the remaining ash after incineration is treated with acid, and the proportion of the acid-insoluble fraction is determined.

This index represents the resistant and acid-insoluble minerals:

• Particle Size

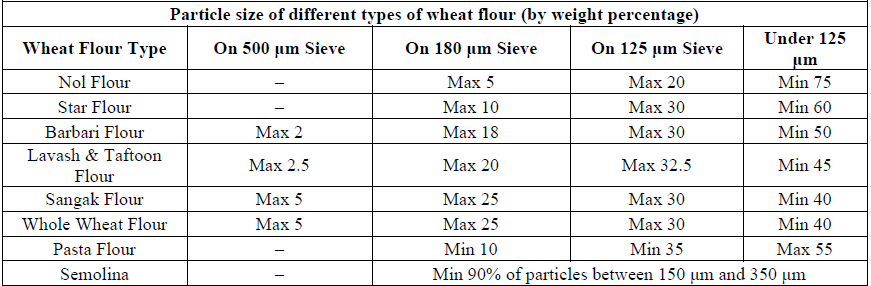

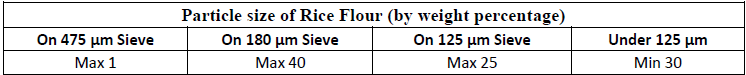

One of the key factors in determining flour quality is the uniformity of particle size and shape. Flour particles should be as consistent as possible in size and shape to improve the texture and quality of the final product, such as cakes or bread, which depend on processes like water absorption, dough uniformity, and so on.

To assess particle size and shape uniformity, a sieving test is performed using standard sieves. In this test, flour is placed on sieves with specified mesh sizes, and the percentage of particles that remain on the sieve (larger than the mesh size) or pass through the sieve (smaller than the mesh size) is measured. Based on these data, the uniformity and particle size distribution of the flour are determined.

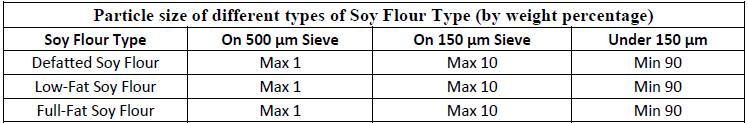

Below are the sieve sizes and the percentages of flour passing through (under-sieve) and remaining on the sieve (over-sieve) according to the standards for each type of flour:

• Acidity and pH

One of the most important tests for evaluating flour shelf life (freshness or staleness) is the acidity test (which indicates the amount of acid in a material) and pH measurement (which indicates the acidity or alkalinity of a material). Generally, flour pH ranges between 6 and 6.5.

Measuring the acidity and pH of flour helps to determine its storage time, likelihood of spoilage, and the use of additives, as follows:

- Typically, older flour has a lower pH and higher acidity.

- Microbial activity can lead to the breakdown of carbohydrates (including sugars and starch, the main energy sources) and the production of acids such as lactic acid, resulting in increased acidity and decreased pH.

- Additives can alter the acidity and pH. For example, bleaching agents reduce pH and increase acidity.

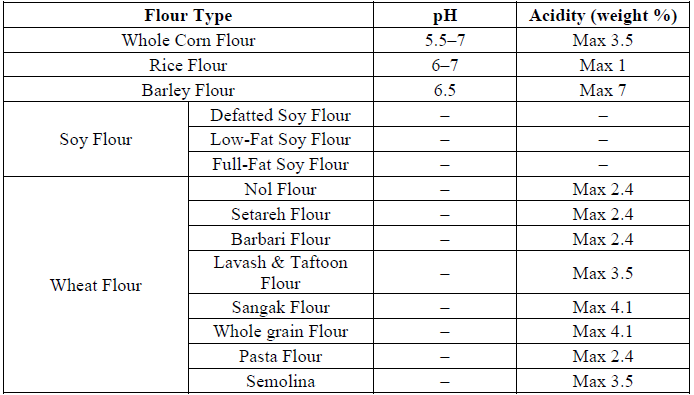

The permissible limits for acidity and pH in different types of flour according to the relevant standards are presented in the table below:

• Enzymatic Activity (Falling Number)

Flours naturally contain enzymes, and since they are high in starch, alpha-amylase (the enzyme responsible for starch breakdown) is also present. Unlike other flour enzymes that generally do not cause problems, the level of alpha-amylase activity can significantly affect dough structure.

The Falling Number (FN) test is used to assess alpha-amylase activity. In this method, flour is mixed with water and heated so that its starch gelatinizes. Then, the time required for a stirrer to move from top to bottom of the mixture is measured. Generally:

- Higher alpha-amylase activity results in a shorter time and a lower Falling Number.

- Lower alpha-amylase activity results in a longer time and a higher Falling Number.

A low Falling Number (high enzymatic activity) reduces starch stability, producing sticky dough that may burn on the surface but remain uncooked inside during baking. Conversely, a high Falling Number (low enzymatic activity) increases starch stability, resulting in dense, low-volume bread.

Measuring the Falling Number is therefore a crucial indicator for assessing flour quality and predicting its behavior during baking, allowing bakers and manufacturers to achieve high-quality dough and final products.

• Protein and Gluten

Protein is one of the valuable components of flour, and gluten is a key protein fraction that plays a vital role in the structure, volume, texture, and quality of final products like bread or cakes. When flour is mixed with water and kneaded, gluten forms a cohesive, elastic, and flexible network that can trap gases produced during fermentation, resulting in leavened, porous bread.

For making high- or medium-volume bread, flour with a high gluten content is essential, as the strength of the gluten network maintains product structure and volume. Conversely, products like cakes require flour with lower gluten content to achieve a soft, delicate, and uniform texture.

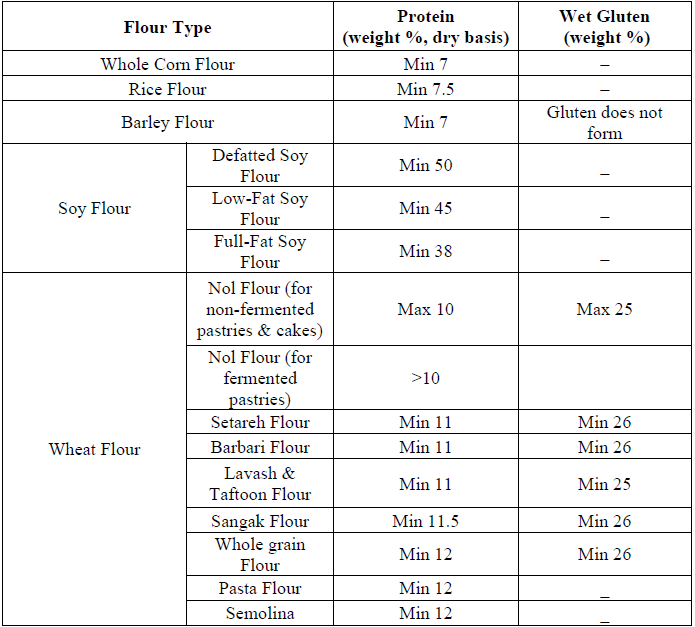

The permissible limits for protein and gluten content in different flours according to the Iranian national standards are provided in the table below:

• Moisture Content

The moisture test determines the amount of water in flour. Moisture directly affects processability, shelf life, and final product quality, influencing baking time, texture, and overall product characteristics.

For example, flour with too high or too low moisture alters its weight, affecting the actual amount of flour used in formulations for bread or cakes, which may result in overly dry or overly moist products. Moisture variation introduces significant errors in flour usage and ultimately reduces product quality uniformity.

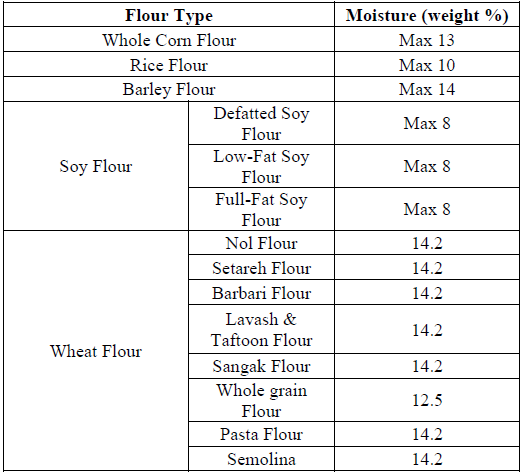

From a safety perspective, high moisture can promote microbial growth and spoilage, decreasing shelf life during storage. The permissible moisture content for different flours is provided in the table below:

- Pesticide Residue Testing

Pesticides play a vital role in protecting crops from pests, increasing yield, and ensuring post-harvest storage. However, residues above permissible limits in food pose serious public health and environmental concerns. Residues may result from:

- Excessive pesticide application

- Ignoring the pre-harvest interval

- Using banned pesticides

- Simultaneous application of multiple pesticides

- Low-quality pesticides

- Improper calibration of spraying equipment

During flour production, removal of the outer grain layer reduces most surface pesticide residues. However, pesticides that penetrate the grain may persist in the final flour. Chronic exposure can cause liver disorders, immune suppression, infertility, neurological issues, and even increase cancer risk.

Testing for pesticide residues in flour is conducted according to Iranian National Standard No. 13120, which specifies maximum residue limits for various pesticides in cereals.

Iran National Standard – No. 13120

- Mycotoxin Testing

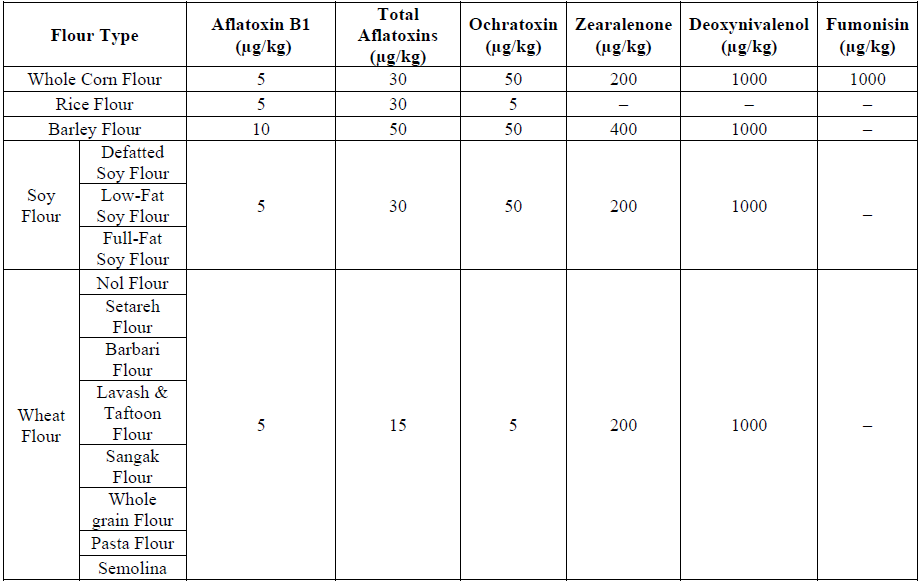

Cereals and legumes, during cultivation, harvest, transport, and storage, may be exposed to high moisture, heat, and poor ventilation, promoting the growth of fungi such as Aspergillus, Penicillium, and Fusarium, which produce mycotoxins.

Key mycotoxins include aflatoxin B1, ochratoxin A, zearalenone, deoxynivalenol, and fumonisins, which can cause liver and kidney damage, immune suppression, hormonal disruption, and cancer.

Mycotoxins are heat-stable, and standard baking or cooking processes cannot completely inactivate them. Thus, early detection and measurement during flour production are critical for food safety. Mycotoxin testing is performed according to Iranian National Standard No. 5925, which sets maximum limits for these toxins in food products including flour:

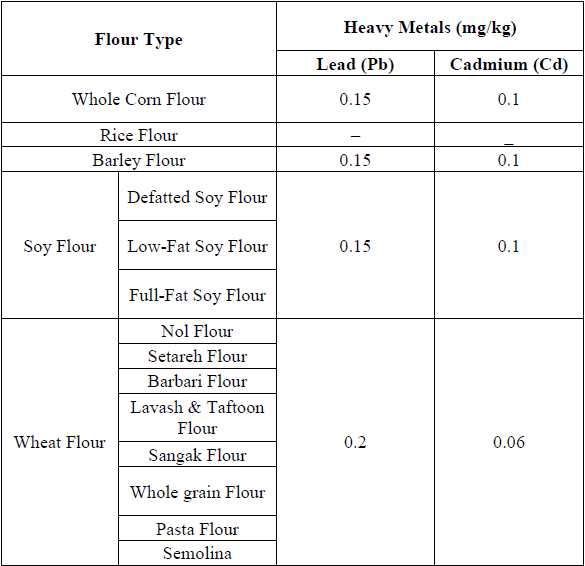

- Heavy metals test

Flour can be contaminated with heavy metals during production, mainly from raw materials (soil, water, fertilizers) or processing equipment. Heavy metals accumulate in the body, especially in the liver, kidneys, lungs, and bones, causing long-term health issues such as neurological disorders, kidney disease, immune suppression, and cancer.

Regular quality control and testing in factories are essential. Iranian National Standard No. 12968 specifies maximum allowable levels of heavy metals in food products:

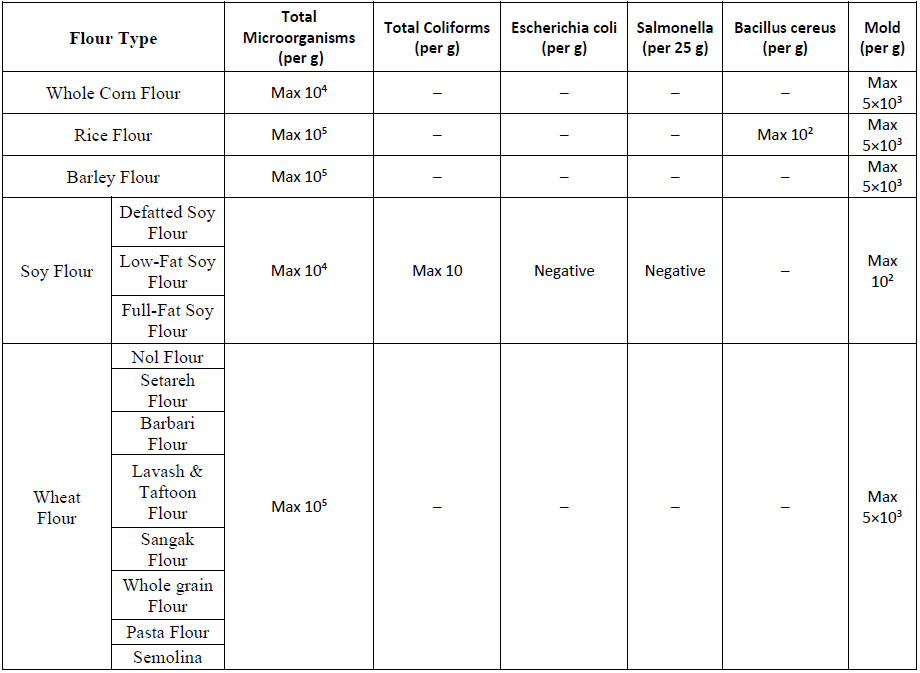

- Microbial Testing

Measuring microbial contamination is an important indicator of food safety. Flour is often made directly from raw grains without thermal treatment, so microbial contamination from farm to mill can be transferred to flour.

Sources include:

- Pre-harvest contact with soil, manure, contaminated water, or animal feces

- Poor post-harvest storage, pest activity, or unhygienic equipment

Microbial testing of grains and flour is essential for identifying and controlling contamination, ensuring consumer health and food safety. Permissible microbial limits are defined in Iranian Standard No. 2393:

Marjaan Khatam Laboratory, Your Reliable Partner for Specialized Flour Testing

Marjaan Khatam Food Laboratory, the first and most reputable food laboratory in Iran with ISO 17025 certification and over 23 years of experience in food quality control, operates in collaboration with the Iranian National Standards Organization and Food & Drug Administration, with three branches in Iran (Tehran, Bandar Imam Khomeini, Khorramshahr) and one abroad (Russia). The laboratory provides consultation, sample collection, and standard-compliant testing for food safety and quality.

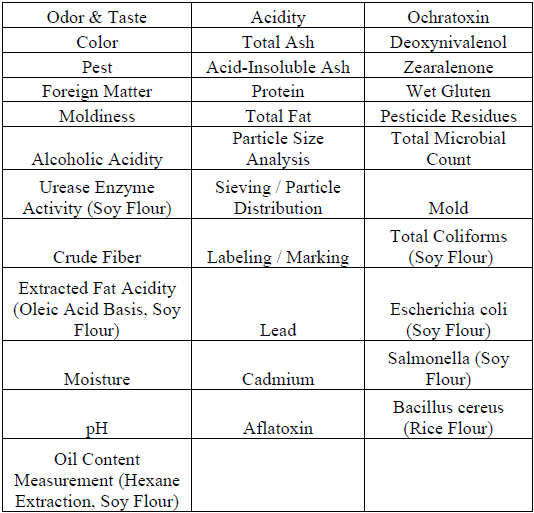

Approved Tests by Marjaan Khatam Laboratory in Compliance with the National Standards Organization

The Marjaan Khatam Food Laboratory, officially licensed by the Institute of Standards and Industrial Research of Iran (ISIRI), is authorized to conduct the mandatory tests required in the process of approval and supervision of flour safety and quality. These tests include:

Approved Tests by Marjaan Khatam Laboratories in Compliance with the Food and Drug Organization

Marjaan Khatam Laboratory, officially licensed by the Food and Drug Organization, is capable of conducting the mandatory tests required in the process of issuing health permits and monitoring the safety of flour. These tests include:

For contact and sample submission, please visit the link below:

https://marjaangroup.com/contact-us